A Game Changer in the Industry

Want to know more about LIMWORKS? LIMWORKS was created to fill a void in the Liquid Injection Molding industry. Our proprietary injection technology has been a game-changer in the industry, and we are driven by our passion for constantly innovating and trying to design machinations that can deal with the complex challenges of the market today while keeping the process as less labor-intensive and highly cost-effective as possible

Rising Above Challenges

The design of standard LIM machinery is based on the reciprocating screw, and check ring injection systems used originally for molding thermoplastic parts from pellets. While screw injection is effective for thermoplastic materials, it creates challenges for 2-part liquid silicone materials that must be cleaned out of the screw path to change material or color or prevent the material from curing in an idle machine.

One method of cleaning the injection system in a screw injection machine involves hours of downtime with disassembly and cleaning of the screw, and another common method of changing materials by purging results in a significant amount of material waste.

LIM has been a good fit for products with an established high volume that can afford both a substantial investment in equipment and an extended tooling development time. The downside of LIM has been the hours of change overtime at the end of a production run to chemically clean the screw and check ring and setup to start another production run. The time and difficulty of starting and stopping have made LIM cost-prohibitive for both short-run production and use for product and tooling development for high volume silicone parts until 2021.

ProChanger H1 is Born

ProChanger H1 was developed by us from the ground up just for LSR. The process took over five years of meticulous planning, testing, and development. It involved a team of seasoned industry experts with a sound knowledge of designing various injection molded parts, tooling, automation, and machine design.

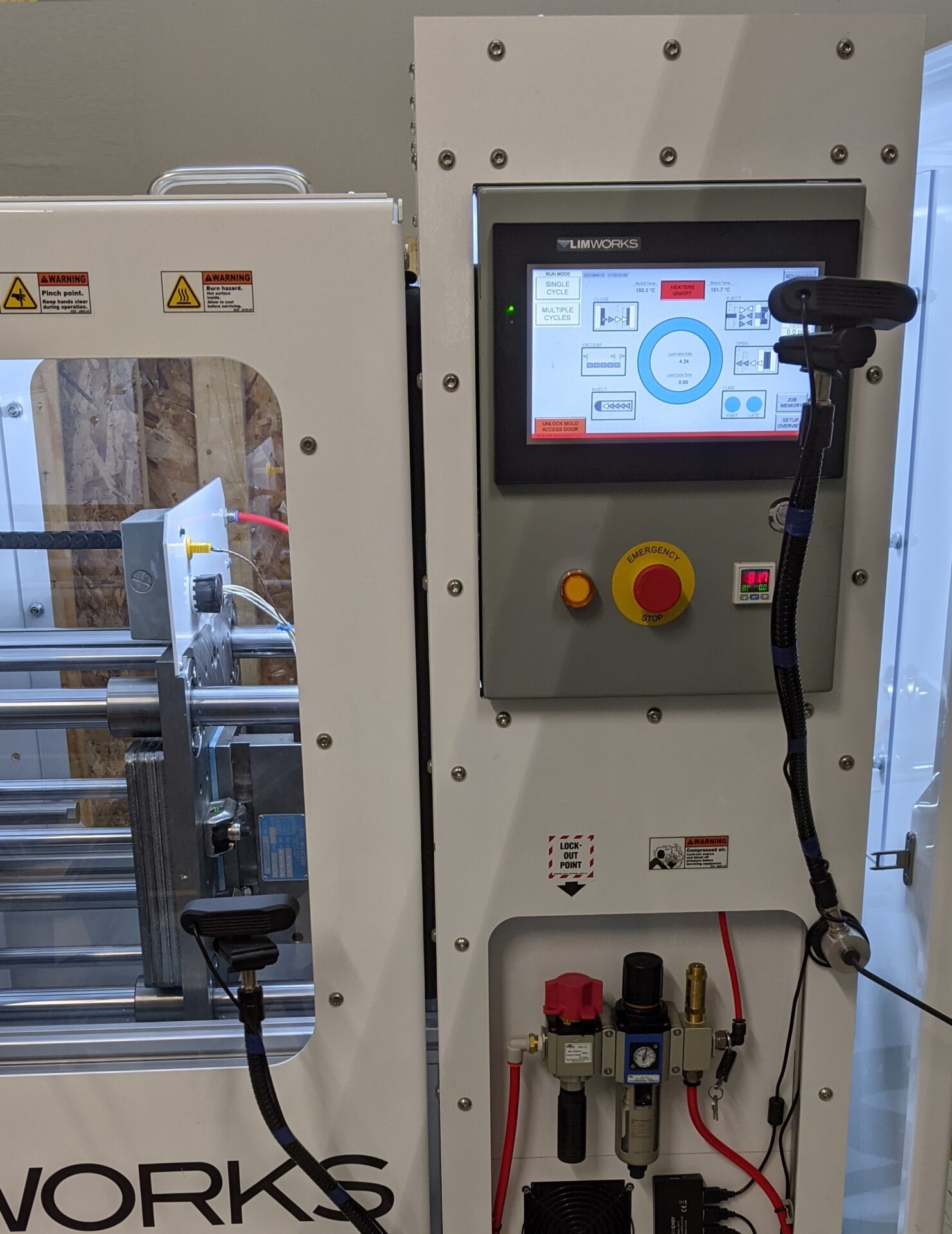

The precision modular injection system provides all of the quality and cost benefits of LIM without the costly setup and shut down. The ProChanger H1 horizontal molding machine brings cost-effective Liquid Injection Molding cost to short-run production, allowing multiple SKUs and different silicone materials to be molded back-to-back with no downtime for material changeover and no harsh chemicals needed for cleaning molding equipment. In addition, the ProChanger H1 provides a cost-efficient venue for developing parts and validating critical tooling features before building expensive high-volume tooling.

LIVE MOLDING VIDEO CONFERENCE

See the benefits of instant material change and the injection path vacuum in person at our showroom or live by video conference. We have tools and material on hand. Some materials are premixed then freezer stored and instantly ready for molding demonstrations. Three machine mounted webcams can simultaneously display the mold tool, HMI screen and Injection system during the molding cycle. Contact us to schedule your own live “mold cam” demonstration.