Precision LSR Molding Machine

ProChanger H1 - Benefits

- Multipurpose machine from shop to lab. Ideal for 24/7 and single shift production, engineering labs & tool shops.

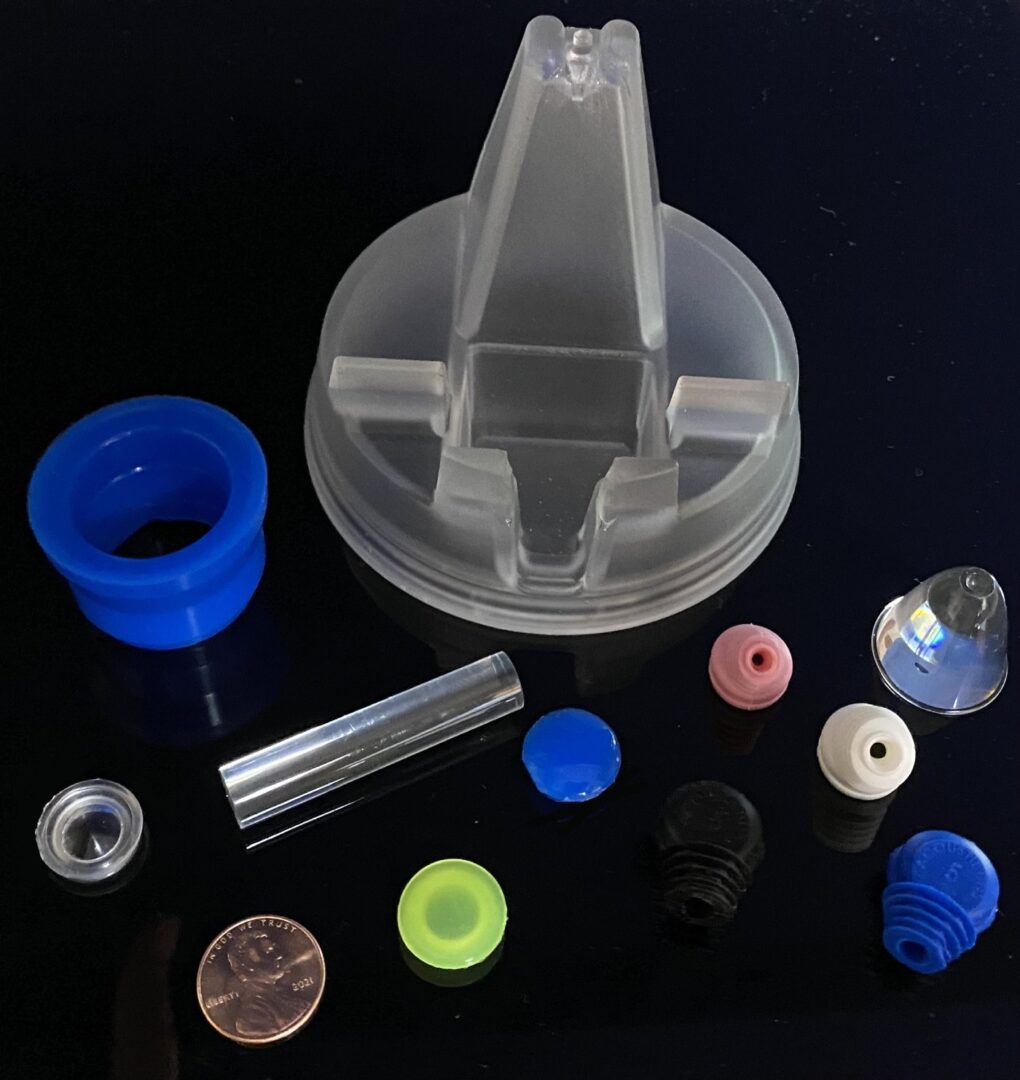

- Reduce short run production cost. LIMWORKS proprietary Injection Module™ system allows multiple SKU’s and colors to be molded back-to-back in a single shift using premixed material cartridges and interchangeable injection modules.

- Mold up to an 80cc Shot in a small space. Micro-sized up to larger 80cc silicone parts produced in a small footprint.

- Accelerate product development. Use low volume tool tests to validate high volume tool design and ejection.

- Precise and repeatable shot size. Superior control with LIMWORKS exclusive tapered seat rotary directional valve and a servo driven plunger injection system.

- Improve cavity fill without tool venting. LIMWORKS proprietary Injection Path Vacuum™ extracts air at the nozzle seat and thru the injected material path just prior to nozzle-seat contact. Tool vents and related costs are often not needed.

- Increase production rate with air eject. Integrated air ejection offers both automated part ejection and assists manual part ejection.

- Eliminate machine down time with offline, chemical free cleaning. Injection Module™ can be cleaned by bake curing the LSR inside, then peeling the solidified LSR from the module off line and without harmful chemicals.

Why Choose Us

Our Liquid Injection Molding (LIM) system provides all of LIM’s quality and cost benefits for molding a high quality silicone part without costly setup and shut down. * Precision finished or rapid cut cavities and cores can be used to quickly validate part and tool design. * Vacuum at nozzle seat extracts air through the material injection path allowing the elimination of tool vents and related costs. *All uncured material is contained in the injection module which can simply be removed, replaced, and cleaned off-line when changing materials.